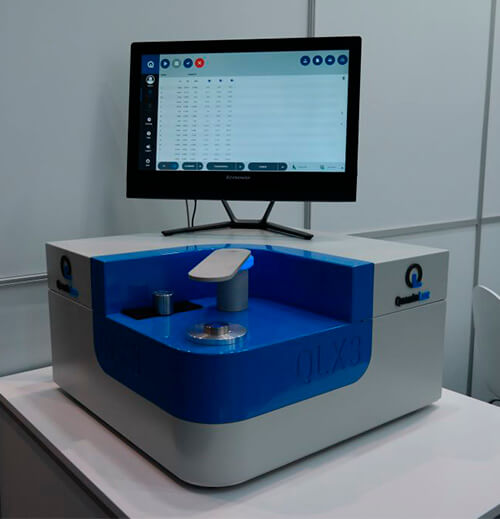

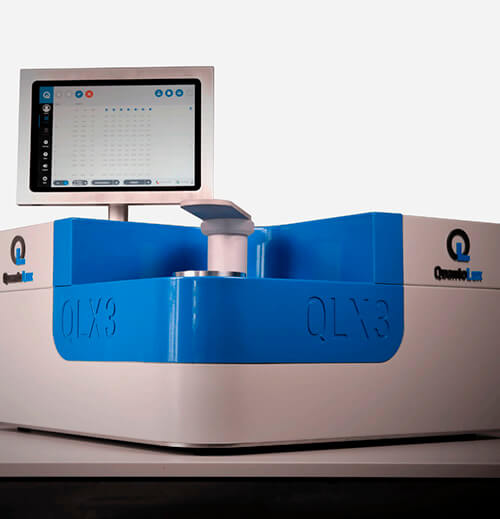

QLX3 is a benchtop laser spectrometer for many applications. It determines the elemental composition of solid matter within few seconds and minimum operator activity.

Its innovative concept overcomes many of the limitations and restrictions of other technologies. Latest developments in laser and detector technology have enabled us to create this unique analytical instrument.

Initially the focus is on all types of metal applications. But the technology is also suitable for various other applications in minerals & mining, cement, slags, etc.

QLX3 is a benchtop laser spectrometer for many applications. It determines the elemental composition of solid matter within few seconds and minimum operator activity.

Its innovative concept overcomes many of the limitations and restrictions of other technologies. Latest developments in laser and detector technology have enabled us to create this unique analytical instrument.

Initially the focus is on all types of metal applications. But the technology is also suitable for various other applications in minerals & mining, cement, slags, etc.

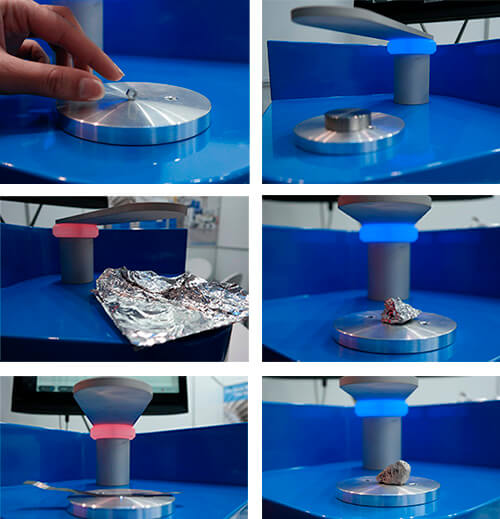

The handling of samples at the QLX3 sample stage is very simple. Any compact sample larger than one millimeter can directly be analyzed. Adapters or special preparations are typically not needed.

Sample preparation, too, is very easy. For metal samples metallic, clean surfaces are required, not specifically smooth or rough.

For powders or granulates, pressed pellets or fused beads need to be prepared.

The QLX 4.0 software has an easy-to-use interface and is operated via touch screen. It features work modes for analysis, sorting, and material identification (PMI). The grade library is open and can freely be edited. Colors highlight deviations from grade specs.

Carbon equivalents, the sum of trump elements and other “pseudo element” formula can be created in the settings menu and added to the display.

Results can be saved in an SQL database. Customized reporting via PDF or into Excel is also supported.

QLXUp! is an optional update service that keeps the QLX 4.0 software up to date.

New software version will automatically be downloaded from the QuantoLux server and the user will be notified.

High resolution optical systems, a powerful pulsed laser are important pre-requisites for outstanding analytical performance.

Decades of experience in QuantoLux’ application team enable complex analytical solutions and expert calibrations.

QLX3 offers a wide portfolio of calibrations. All metal bases can be covered. And all can be installed on the instrument or added any time later! A real powerful tool – shaping the future of OES!

Please inquire with your analytical needs and we will check for you!

To seamlessly bring your QLX3 into operation, it comes with a controller that has a pre-installed QLX 4.0 software, calibrations, and online services.

The instrument offers a choice of two different controllers:

Thirdly, end-users can use their own computer hardware to control the instrument.

QLX3 follows a unique design concept. It unites the benefits of both worlds, x-ray fluorescence analyzers (XRF) and spark spectrometers and avoids the pitfalls at the same time.

In detail this means:

capable to excite any material

full analytical scope! No lock-out elements, no long measurement times.

The system covers all relevant elements within 3-5 seconds at low limits of quantification

maintenance-free, no brushing, no cleaning

touch-screen allows easy operation.

high sample throughput, no heating up

QLX3 features latest technologies in excitation, detection and digital concept.

In contrast to classical spark spectrometers, QLX3 uses a laser to excite the sample and generate a plasma. We call this laser-OES, but the technology is also referred to as LIBS.

It offers some distinct advantages:

small burnspot

no or low argon

no electrode cleaning, no cross contamination

The detectors used in QLX3 are CMOS sensors. They are technically superior to previously used CCDs in many aspects: spectral response, dynamic range, speed. They allow single-pulse detection, a technology used for micro-analysis, depth profiling, and also to identify outliers and, thus, improve the precision of the instrument.

Finally, various digital services and general IoT functions, provide value propositions unseen in this type of instrument before.

Currently the below listed applications are available for QLX3.

If you have a special requirement, please do not hesitate to contact us.

Steel Alloys (Fe base) – Low alloyed steels, carbon steels, mild steels, stainless steels

Aluminium & its Alloys (Al base) – Low Alloy, AlSi, AlMg, AlCu, etc.

Copper & its Alloys (Cu base) – Pure Copper, Bronces, Brass, Gunmetal, etc.

Nickel & its Alloys (Ni base) – Low Alloy, Monel, Nimonic, Inconel, Hastelloy, Incoloy, etc.

Cobalt & its Alloys (Co base)

Zinc & its Alloys (Zn base) – Primary, Remelt, Zamac, etc.

Magnesium & its Alloys (Mg base)

Titanium & its Alloys (Ti base)

Tin & Solders (Sn base)

Lead & Batteries (Pb base)

Quality control in metal processing industries

Process control in automotive industries

Contract labs & inspection companies

Academia and Corp R&D

Recycling & metal trading

Minerals & Mining

Cement & builing materials

Ceramics

| Dimensions | 585 x 585 x 300 mm (W x D x H) |

| Weight | Ca. 35 kg / ~77 lbs |

| Operating Temperature | 5 to 35° Celsius |

| Plasma Source | Q-switched diode pulsed laser, 1064 nm, Class 1 |

| Optical Systems | dual optic |

| Detectors | Complementary Metal-Oxide Semiconductor (CMOS) |

| Spectral range | UV-VIS-nIR |

| Sample stage | 1-3 mm aperture |

| Max. Power consumption | 300 W, <0.5 W in stand-by |

| Processor | Intel i3 or better |

| Operating System | Windows 10 |

| RAM Memory | 4+ GB |

| Hard Disk | 128+ GB |

| Interfaces | Wifi, Bluetooth, USB |

| Analytical Apps | All metal bases. Minerals & mining, and other apps on request. More details on analytical coverage and performance can be found in the respective application sheets |

| Typical Detection Limits | d-ppm |

| Typical Measuring Time | 3-5 seconds |

| Working Modes | Analysis, PMI, Pass/Fail Sorting |

| Gas purge | Argon for spectrometry recommended „no gas“ mode for certain apps |

| Gas flows | Idle Mode, Stand by, Low Flow, Analytical Flow |

| Display | 13“ or 22″ |

| Security | User-specific profiles with user levels and password protection |

| Drift monitor | Classical Standardisation and type standardisation single drift monitor sample for dynamic correction |

| Grade library | editable library |

| Regulatory | CE, RoHS |

subscribe to receive promotions and offers, and download the content

You have successfully subscribed to the newsletter

There was an error while trying to send your request. Please try again.

Thanks for your download!

SAVE CLOSE THIS MESSAGE AND CLICK THE PDF YOU WANT TO DOWNLOAD, WE ARE HAPPY TO BE ABLE TO OFFER WHAT YOU WERE LOOKING FOR