The Elcometer 200C Contractor Abrasive Blast Machine is ideal for mobile blasters requiring continuous high production blasting as its large capacity reduces down time refilling the hopper.

Utilising industry standard remote control valves, grit valves and 1¼” (32mm) pipework, the Elcometer 200C Abrasive Blast Machine is highly competitive and easy to maintain.

The Elcometer 200C Contractor Abrasive Blast Machine is ideal for mobile blasters requiring continuous high production blasting as its large capacity reduces down time refilling the hopper.

Utilising industry standard remote control valves, grit valves and 1¼” (32mm) pipework, the Elcometer 200C Abrasive Blast Machine is highly competitive and easy to maintain.

Built to the same high quality as the Elcometer Performance and Performance HP blast pots, the contractor range of blast machines are cost effective, easy to use and Elcometer Engineered for reliability.

UKCA and CE approved, the machines are fully tested and certified to International Standards including PED 2014/68EU and PE(s)R 2016.

The Elcometer Automatic General Valve has a built in fail-safe feature that shuts off both the blast stream and media flow at the handle quickly and safely – reducing wastage.

Standard bore 32mm (1¼”) pipework throughout for reliable airflow performance.

Our high flow concave dish comes complete with a deflector plate for fast filling & operator safety.

Industry standard exhaust manifolds allow air to exhaust through the silencer safely.

45/90° cone to maximise abrasive flow rate.

High performance moisture separator prevents water and oil from entering the blast pot.

Elcometer’s Contractor abrasive blast machines make inspection and servicing easy, thanks to the large doorway access that is wide enough to fit both arms.

Optional sieves & lids are designed to fit over the top of the machine to prevent water ingress, keeping the media dry.

Elcometer 200C Contractor Portable Abrasive Blast Machine Spare Parts |

|||||||

| Item | Part Number | Description | |||||

| 1 | MT32050 | Pop Up Valve | |||||

| 2 | MT32051-3 | Pop-Up Shaft; M200B | |||||

| 3 | MT29611 | 1″ (25mm) Female Equal Elbow | |||||

| 4 | MT28617 | Moisture Separator Assembly | |||||

| 5 | MT32053 | 11/4” Pipe (32mm) | |||||

| 6 | MT29664 | 1/4” (6mm) Bulkhead Connector (x3) | |||||

| 7 | MT32054-3 | Twinline Air Hose Assembly (Yellow & Green) | |||||

| 8 | MT28627-5 | Pop-Up Valve Ring (x5) | |||||

| 9 | MT32052 | Deflector Plate with Fasteners | |||||

| 10 | MT32035 | 1″ (25mm) Backnut | |||||

| 11 | MT29673 | 1″ (25mm) Female / Female Union Taper Seat | |||||

| 12 | MT32036 | 1″ to 3/4” Reducing Hex Nipple (25 x 19mm) | |||||

| 13 | MT32037 | 3/4” (19mm) 90° BSPP Elbow | |||||

| 14 | MT32038-3 | 3/4” (19mm) Pipe; M200B | |||||

| 15 | MT32039 | 3/4” (19mm) Socket | |||||

| 16 | MT32024 | 1″ (25mm) Male/Female Union Taper Seat | |||||

| 17 | MT32025-3 | 1″ (25mm) Choke Pipe; M200B | |||||

| 18 | MT32027 | 1″ (25mm) Equal T | |||||

| 19 | MT29681 | 1″ (25mm) Exhaust Plug | |||||

| 20 | MT32028 | 11/4” to 1″ Hex Reducer (32 x 25mm) | |||||

| 21 | MT32044 | RCV c/w Silencer and Union Elbow | |||||

| 22 | MT29656 | Petcock Valve Assembly – (Red Handle) | |||||

| 23 | MT32032 | 11/4” (32mm) Male/Female Equal Union Taper Seat | |||||

| 24 | MT32029 | 11/4” (32mm) Equal Pitcher T | |||||

| 25 | MT30094 | 11/2” (38mm) Choke Valve Handle | |||||

| 26 | MT32032 | 11/4” (32mm) Ball Valve | |||||

| 27 | MT32033 | 11/4” (32mm) 60° Cone Male/Male Adaptor | |||||

| 28 | MT32043 | Silencer c/w Union Elbow | |||||

| 29 | MT28616 | Elcometer Inspection Hatch Door | |||||

| 30 | MT28613 | ElcoFit™ Door Sealing Gasket | |||||

| 31 | MT32049 | Elcometer Inspection Door Fixings | |||||

| 32 | MT32048 | Elcometer Inspection Door Yoke | |||||

| 33 | MT32047-3 | 2355mm Single Spare Wheel Kit | |||||

| – | MT29603-4 | Contractor Decal Kit | |||||

| – | MT32046-3 | 11/4” (32mm) Pusher Hose Assembly for Elcometer 200C Contractor Blast Machine | |||||

Elcometer 200C Contractor Abrasive Blast Machine – 12bar (174psi) |

|||

| Capacity1 | |||

| Volume | 200 Litres | 7.06cu ft | |

| Garnet Grit | 468kg | 1031lbs | |

| Steel Shot | 880kg | 1942lbs | |

| Model: | Portable | ||

| Valve: | Standard Grit Valve (SGV) | ||

| Dimensions | |||

| Pot Diameter: | 610mm | 24″ | |

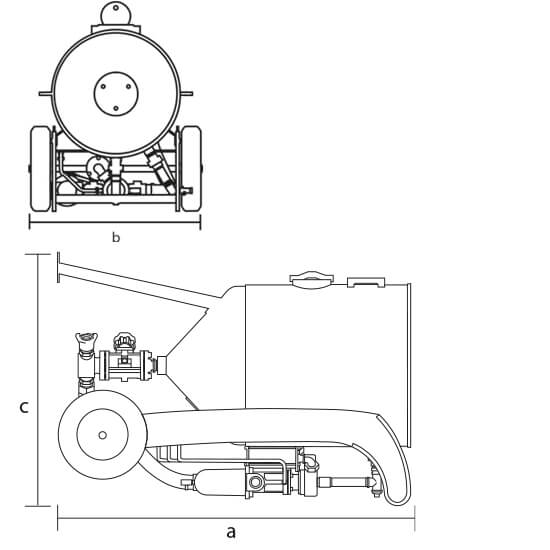

| Height (a): | 1380mm | 54″ | |

| Width (b): | 794mm | 31″ | |

| Depth (c): | 1109mm | 44″ | |

| Weight | 205kg | 452lbs | |

| Pipework Diameter | 32mm | 11⁄4″ | |

| Maximum Working Pressure (WP)2: | 12bar | 174psi | |

| Operating Temperature Range: | 0 to 60oC | 32 to 140oF | |

Kit Contents |

|

| Part Number | M200B-G |

| Abrasive Blast Machine | ■ |

| Pressure Test Certificate | ■ |

| Remote Control Valve with Air Manifold, Exhaust & Silencer | ■ |

| 10m (32.8ft) Pneumatic Control Hose & Deadman’s Handle (DMHII) | ■ |

| Choke Valve and Pusher Line | ■ |

| Abrasive Metering Valve with Mixer T and Metal Pot Coupling | ■ |

| Moisture Separator | ■ |

1 Aluminium & steel shot capacity figures based on typical media bulk density. Note that bulk density varies according to media size and grade.

2 Do not operate this abrasive blast machine unless there is an appropriate safety pressure relief valve within the pressurised system as a whole.

subscribe to receive promotions and offers, and download the content

You have successfully subscribed to the newsletter

There was an error while trying to send your request. Please try again.

Thanks for your download!

SAVE CLOSE THIS MESSAGE AND CLICK THE PDF YOU WANT TO DOWNLOAD, WE ARE HAPPY TO BE ABLE TO OFFER WHAT YOU WERE LOOKING FOR